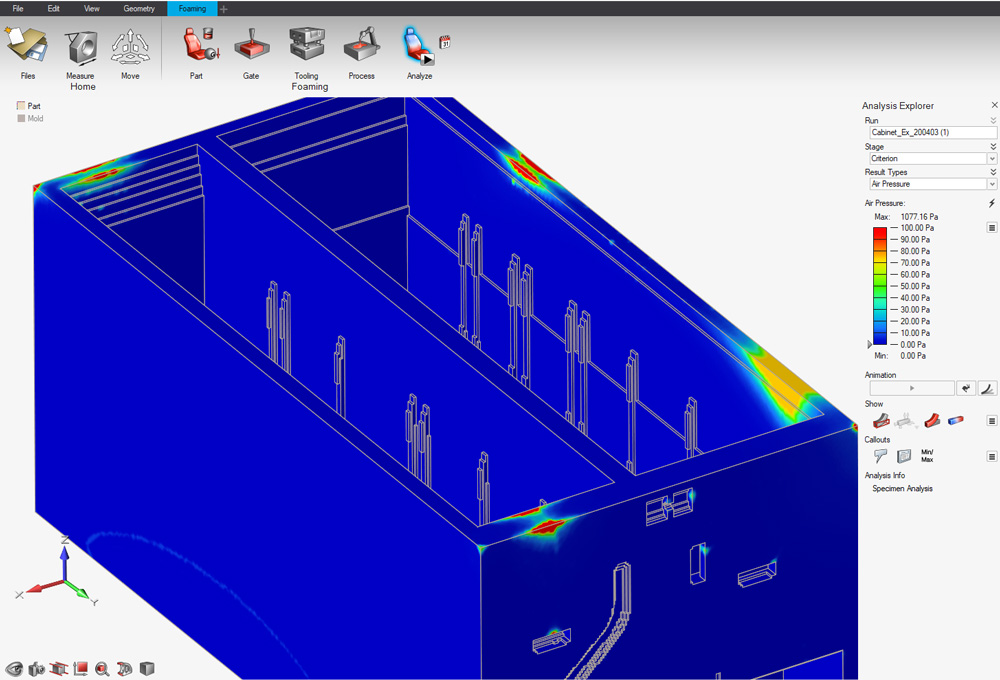

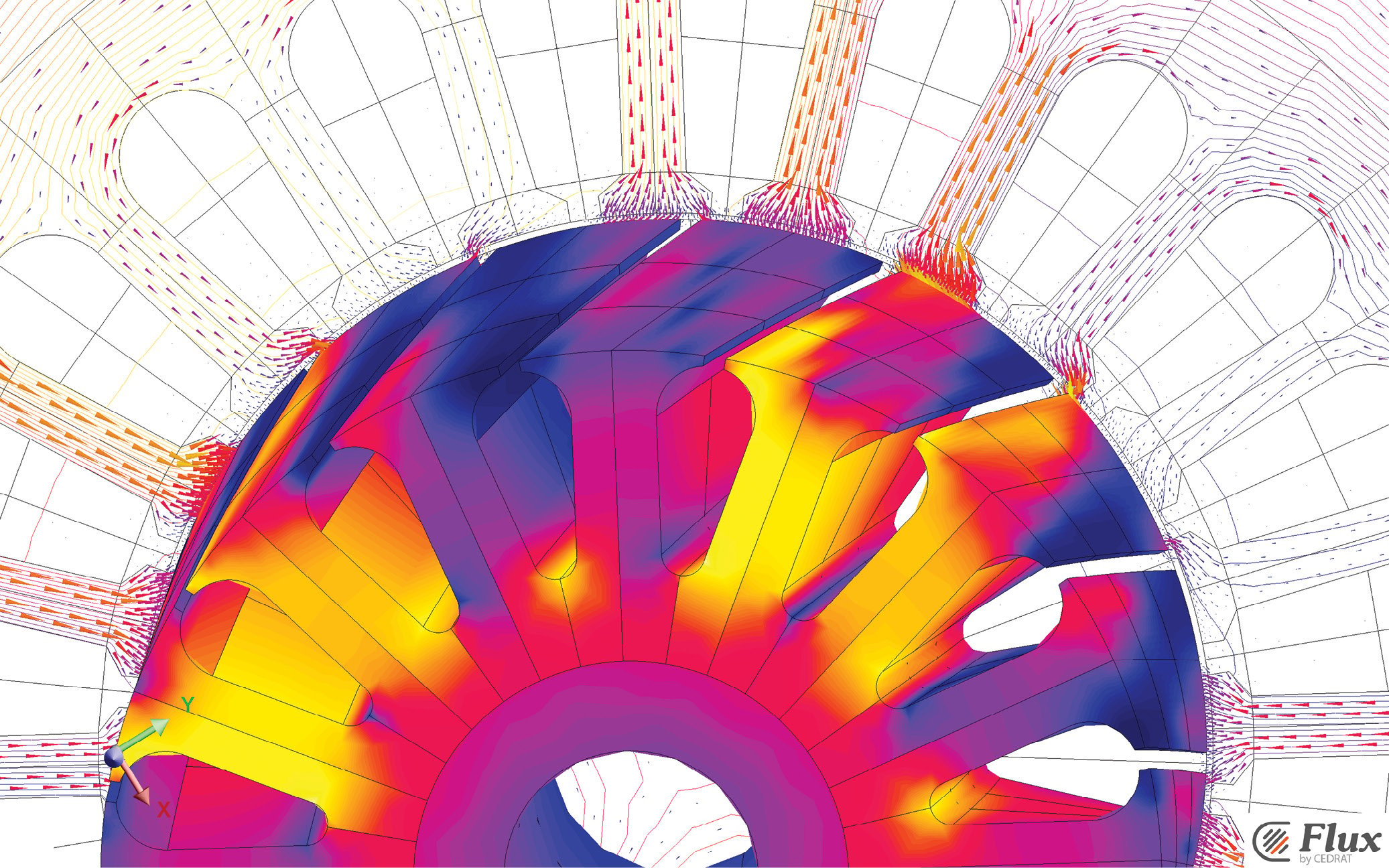

Users develop models quickly and easily by taking advantage of Parasolid’s extensive mechanical CAD modeling functions, such as adding, subtracting, intersecting, hollowing, tapering and blending solid geometry.Įngineers can intuitively fashion complex organic shapes with non-uniform rational b-spline (NURBS) surfaces created along user-defined guide curves or automatically fitted between existing surfaces. At the same time, the modeling tools need to be intuitive enough for design engineers to master quickly and easily.Īltair selected the Parasolid® software geometric modeler, part of the Xcelerator™ portfolio of solutions and services from Siemens Digital Industries Software, because it offers Altair Inspire™ users the widest array of 3D modeling capabilities available. Mix-and-match 3D modeling in a single intuitive applicationĪltair recognized that a leading simulation-driven design application needs to offer a comprehensive geometric modeler to capture the diversity of form in manufactured products across a broad range of industries, and the range of preferred methods used in their design. Inspire Print3D simplifies the identification and correction of potential deformation, delamination and excessive heating issues before building a part.Provided customers a sophisticated, integrated 2D sketcherĪltair’s comprehensive, openarchitecture solutions for data analytics, simulation, and high-performance computing (HPC) enable design and optimization for high-performance, innovative and sustainable products and processes in an increasingly connected world. Reducing expensive trial and error by simulating part build, cooling, cutting and springback, Inspire Print3D delivers designs having the fewest supports, optimally oriented on the print bed.Įngineers can quickly understand changes to process or design that effect manufacturing efficiency then export part and support structure geometry to major printer preparation software for printing. By capturing behavior independent of the printer type, with Inspire Print3D designers can evaluate and easily modify critical process variables. The easy to use advanced thermo-mechanical simulation enables design engineers to develop parts ready for additive manufacturing. It provides a fast and accurate toolset for the design and process simulation of selective laser melting (SLM) parts.

Inspire Print3D enables teams to cut product development and additive manufacturing costs by reducing material usage, print times and post processing.

0 kommentar(er)

0 kommentar(er)